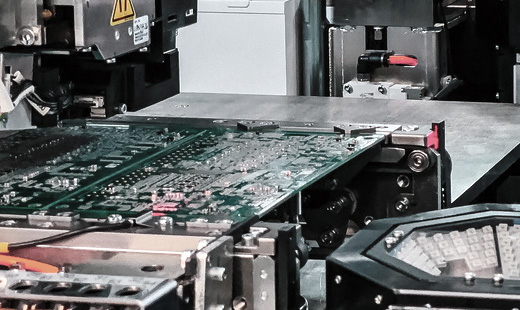

An integrated approach to production is the key to success. We provide a full range of electronic manufacturing services:

- PCB fabrication

- Components sourcing

- SMT and THT assembly

- Uploading firmware

- Functional testing

- PCB washing and cleaning

- Conformal coating

- Final mechanical assembly and housing

- Antistatic packing

We perform the assembly of the entire scope of electronic components (chip components from 01005, BGA and Flip-Chip, Fine-pitch elements with a pitch of leads from 0.3 mm, etc.), respecting the requirements for installation accuracy, ESD protection, soldering temperature conditions (including lead-free alloys) and many others specified by IPC-A-610 (electronic system assembly quality standard).

A well-developed, multi-stage quality control system at all stages minimizes the risk of manufacturing defects. Our approach to quality control does not change depending on the quantity or purpose of the assembled products - we check every manufactured unit at all stages of the technological process.

The flexibility of our production process allows us to assemble any number of products - from single units to tens of thousands.

In assembly factory:

Our manufacturing capabilities allow us to produce not only the prototypes but also small and medium series of electronic products. The manufactured products will fully comply with the technical specifications and the standards of the International Association of electronics manufacturers and IPC standards.